History of things: iron (229 photos)

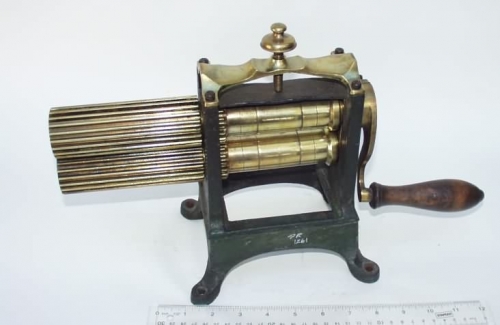

We are accustomed to the modern iron, which is lightweight and made of plastic, but earlier irons were completely different. There were a lot of ironing devices that we do not encounter in everyday life, and we have already forgotten about them. The first ironing device was most likely a flat, heavy stone. In the cave paintings of the ancient Aztecs, the ironing process is depicted as follows: clothes were spread out on a flat surface, pressed on top with a stone and left for a while under this press. In the 4th century BC. The Greeks invented a method of pleating clothes using a metal rod like a rolling pin. Two centuries later, the Romans beat wrinkles out of clothes with a metal hammer heated to a high temperature. In Russia, there was a method of ironing using a ruble and a roller. Dried laundry was wrapped around a smoothly planed stick and rolled over the tabletop using a corrugated board. This principle is still used in some ironing machines. An iron with burning coals inside appeared only in the middle of the 18th century. Before this, clothes were ironed with a tool very similar to a large frying pan. The closest predecessor of the modern iron was a brazier with coals. It looked almost the same as an ordinary frying pan: hot coals were placed inside a cast-iron frying pan with a handle and they began to move this kind of “frying pan” over the clothes. It is clear that this “iron” was not particularly convenient and safe: working with it was awkward, sparks and small coals flew out of the brazier every now and then, leaving scorches and holes on clothes.

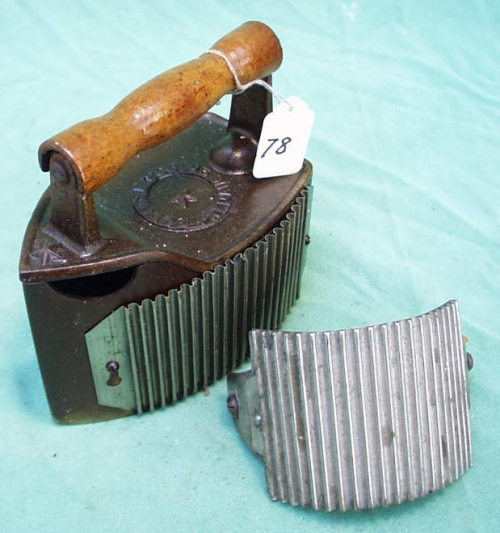

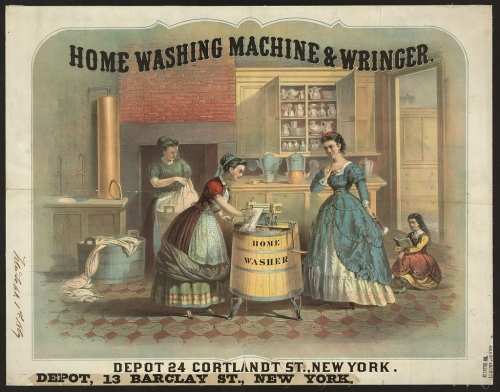

Over time, they began to use two irons: while one was heating up on the stove, the other was ironing. The simplest irons are heating ones. Before use, cast iron monoliths were heated in an oven. Irons for fabric weighed differently - from one to 10 kilograms. Another ancient type of iron is cast iron, heated over an open fire or in a hot oven. They appeared in the 18th century and were still produced in our country even in the 60s. XX century: despite the fact that the electric iron was invented a long time ago. This happened because many houses did not yet have sockets. The cast iron iron took a very long time to heat up - at least 30 minutes, and it was impossible to handle it hot without oven mitts. Therefore, such irons were soon improved: they began to be made in pairs - with one removable handle on two cast iron bases. While one was ironing, the second base was heating up, so the ironing process noticeably accelerated. The frying pan with a handle was replaced by a steam iron. The coals in it were placed inside the body and covered with a lid, and on top, for better traction, a pipe was attached. To make the coals heat better, special holes were made on the sides. Swinging such an iron back and forth increased ventilation. These irons were not particularly convenient or safe: sparks and small coals flew out of the brazier every now and then, leaving scorches and holes on clothes. For better traction, holes were made on the sides; sometimes the iron was even equipped with a pipe. To relight already cooled coals, they blew into the holes or swung the iron from side to side. Since the irons were heavy, ironing turned into a real strength exercise for the arm muscles. In our country, such irons have been known since the 17th century, and in the West, most likely, even earlier. The first written evidence of the presence of irons in use is dated February 10, 1636. In the book of expenses of the royal court it is noted: “The blacksmith Ivashka Trofimov was given 5 altyns, and for that money he installed an iron iron in the queen’s chamber.” In the 18th century, industrial production of “brass” irons had already been established: they were produced by Demidovsky and some other foundries. Large cast iron irons weighed up to 10 kg and were intended for ironing coarse fabrics. To iron thin fabrics and small parts of clothing - cuffs, collars, lace - they used small irons, only half the size of a palm. Instead of coals, a hot cast iron bar was also placed inside the iron. At the end of the 19th century, gas irons began to be produced. The principle of their operation was the same as that of gas stoves: the iron was heated by burning gas. A metal tube was inserted into the body of such an iron, connected at the other end to a gas cylinder, and a pump was located on the cover of the iron. Using a pump, the gas was forced into the inside of the iron, where, when burned, it heated the ironing sole. It is easy to imagine how dangerous such irons were: gas leaks often occurred due to their fault - with all the ensuing consequences: explosions, fires and casualties. At the beginning of the 20th century, an alcohol iron, which was safer than a gas iron, became increasingly popular. Its advertisements could be found in magazines in 1913. It was designed on the principle of a kerosene llama: the surface of the iron was heated with alcohol, which was poured inside and set on fire. The advantage of such an iron was that it warmed up quickly, did not weigh very much, and could be used as a travel option. But this iron was too expensive. The tailor's iron must be heavy, at least a kilogram. Usually at the portThere were several irons of different sizes and weights. There were irons up to 12 kilograms. It's hard to imagine tailoring without an iron. Tailors have a saying: “The tailor makes shit, the iron irons.” It may not sound very nice, but it reflects the essence correctly. Without pressing, stretching and other operations that must be done after each seam (there are special terms for them: ironing, ironing, ironing, ironing) - you cannot sew a good thing. There is even a tailoring term - “tapping”, usually this is done along the edge of the bead or along a thick place in the seam. Such puffs and draperies on dresses and curtains were ironed with special devices. Nowadays there are no such devices; in order to iron a historical dress, you have to rip out the drapery. For draperies and puffs. The sharp end is for the very beginning of assemblies. For figured ironing, scallops and gathers. Scallops, pleats, pleats. Looking at historical underwear and shirts, you can’t help but wonder how they were made and then ironed? There were these special devices, sometimes they were combined with an iron. But at the end of the 19th century, electric irons replaced steam irons. June 6, 1882 can be considered the birthday of the electric iron. It was on this day that the American Henry Seely patented the electric iron he invented. The world's first electric iron's heating element was an electric arc between carbon electrodes, to which direct current was supplied. Early models of electric irons were, like gas irons, unsafe (due to imperfect design they gave a strong electric shock) and capricious in use, so 10 years later, in 1892, the General Electric and Crompton & Co companies modernized the electric iron, starting to use its design includes a heating coil. Such a spiral, hidden inside the body of the iron in front of its sole, was reliably isolated from the body. Finally, irons have stopped shocking their owners, and using them has become much safer. The new design of irons turned out to be so successful that it is still used in new models of irons: it has changed little over the twentieth century. Throughout the last century, the efforts of manufacturers were aimed only at minor improvements in individual elements of the device. So, in the thirties of the 20th century, an important element appeared in the design of an electric iron - a thermostat, which began to monitor the temperature and turn off the heating coil when the required level of heating of the sole was reached. And at the end of the seventies, the soles of the irons themselves changed: they finally ceased to be metal and became glass-ceramic. The new material has significantly reduced the coefficient of friction between the base of the iron and the fabric, and now all modern devices glide over it, which makes ironing much easier.