Dutch Automotive History (part 50) Moskvitch, NSU (118 photos)

After the end of the Second World War, the KIM (Communist Youth International) plant changed its name to the Moscow Small Car Plant (MZMA). He quickly mastered the production of a new model of the Moskvich-400 car. Its design was identical to the pre-war Opel Kadett K-38 passenger car, then a completely advanced vehicle with a monocoque body, independent front wheel suspension of the Dubonnet type, and hydraulic brake drive. An important feature for MZMA was the technological development of the car in Germany for mass production and the availability of equipment received through reparations. There were also very archaic elements in Moskvich. Thus, the rear doors were hung not on the front, but on the rear hinges, the crankshaft bearings remained babbitt filler, and the mechanical type windshield wiper was driven by a flexible shaft from the engine.

MZMA assembled the first car on December 4, 1946. "Moskvich-400" was equipped with a lower valve 4-cylinder engine with a displacement of 1074 cm3 and a power of 23 hp. It had a low compression ratio (5.8) and ran on 66 octane gasoline. The three-speed gearbox had synchronizers in second and third gears. The car with a 4-seater sedan body weighed 855 kg, and its length did not exceed 3.9 m. In addition to the base model, modifications with cabriolet, van and pickup bodies were produced. The production of Muscovites grew rapidly, and in 1950 their annual output exceeded the level achieved by Opel in the pre-war years.

The 1954 modernization failed to significantly improve the car, which became known as the Moskvich-401. Therefore, in 1956 it was replaced by the 402 model, which represented a significant step forward. She received a modern body, beautiful for those times. And although it retained the engine, gearbox and rear axle from Moskvich-401, many elements of its design found application in the Soviet automotive industry for the first time. These are a curved windshield, telescopic shock absorbers, pinless front wheel suspension, a trunk lid that can be locked from the inside, a gearbox with an extension, and a two-spoke steering wheel. Based on the Moskvich-402, cars with station wagon and van bodies, as well as all-wheel drive modifications 410 and 411, were produced. To modernize its models, the plant traditionally had limited funds and developed new units in stages, and in such a way as to ensure their interchangeability with the previous ones. This feature dominated his engineering practice for many years.

Gradually, an overhead valve engine and 4-speed gearbox (1958), a hypoid final drive (1961) and other innovations were introduced. Having retained the old body, the car received the index "407".

The development of the new model "408" occurred gradually. First, in 1963, a modernized engine and an updated front suspension appeared on the transition model "403", and only in September 1964 the Moskvich-408 sedan was put on the conveyor. It had modifications with station wagon and van bodies. The design of these machines was led by Alexander Andronov. The 408 model also underwent a phased modernization, and since 1967 the program was supplemented by the Moskvich-412, equipped with a completely new engine. Since 1968, the enterprise began to be called the Automobile Plant named after Lenin Komsomol (AZLK).

The models “408” and “412” and their various variants were replaced in December 1975 by modifications “Moskvich-2140” (1478 cm3, 75 hp) and “Moskvich-2138” (1358 cm3, 50 hp). ) with standardized bodies, which had export designations “Moskvich-1300” and “1500”. They, like the base models, carried in their design many elements of active and passive safety, which AZLK was the first to introduce in the Soviet automotive industry. The production capacity of the plant then allowed the annual production of more than 180 thousand cars.

But in the global automotive industry, already in the early 70s, there was a turn towards more progressive designs, in particular, towards cars with front drive wheels. Prototypes of "Muscovites" of this configuration were built and tested for many years, but they were not put into production due to lack of investment.

A significant shift occurred in 1986, when production of the front-wheel drive Moskvich-2141 began, the ideological basis of which was the French SIMCA-1307 (SIMCA). However, difficult economic processes in subsequent years did not allow expanding the program and increasing the production of cars. On the contrary, production decreased year by year. In the mid-90s, Moskvich JSC repeatedly stopped production for many months. Only in 1997, thanks to the support of the Moscow government, two long-wheelbase modifications, Yuri Dolgoruky and Prince Vladimir, were produced on the basis of the new Moskvich, which were soon joined by Svyatogor, equipped with foreign-made units and parts. Based on the standard 5-door Moskvich-2141, the 4-door sedan 2142, cargo-passenger variants, taxis, pickups, ambulances and electric vehicles were also built. Simultaneously

But the plant entered into an agreement with Renault on the supply of engines and the creation of a joint venture to assemble Megane family cars in Moscow.

The NSU company was formed on the basis of the Neckarsulmer Radwerke bicycle manufacturing company founded in 1886. In 1892, the first word was shortened, leaving only three letters - NSU. After 8 years, the company was already assembling motorcycles. In 1905, car assembly began under license from the Belgian company Pipe. A year later, based on the Pipa design, a light car "6/10PS" appeared with a 4-cylinder engine with a displacement of 1420 cm3, which was developed by Otto Pfaender. Then several larger cars appeared with engines up to 2608 cm3. In 1909, NSU introduced a small car with a 2-cylinder 1.1-liter side-valve engine, but it was not a success. In 1911, a more successful model was released with a 4-cylinder engine with a displacement of 1131 cm3, which was later increased to 1555 cm3. This machine remained in production until 1913. The largest pre-war NSU was equipped with a 4-cylinder engine of 3399 cm3. Launched in 1913, the "5/15PS" model with a 1.2-liter engine also became popular. She remained in the firm's program until 1926.

One of the most interesting post-war cars was the “5/25/40PS” model with an engine with a displacement of 1307 cm3, equipped with a Roots positive displacement supercharger, which was already used on the “5/30PS” model. Its development was a fairly powerful engine of 1476 cm3, which allowed the car to reach speeds of up to 129 km/h. The racing version of the car won many competitions. It became the predecessor of a passenger car with a side valve engine with a displacement of 1568 cm3. On other machines built in the mid-20s, NSU used 4-cylinder engines of 2100 and 3610 cm3, as well as a 6-cylinder unit of 1781 cm3.

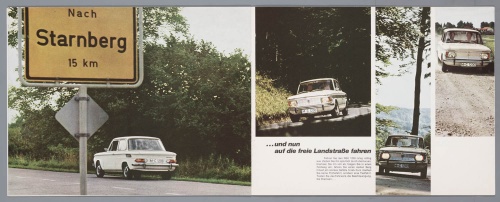

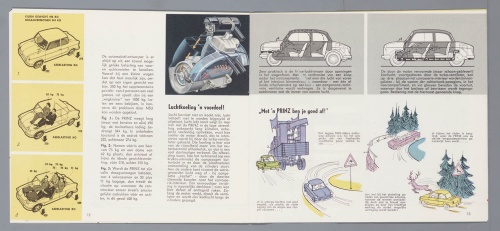

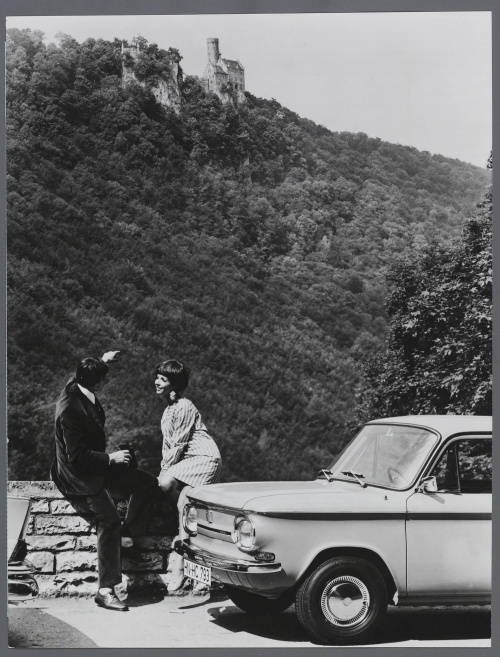

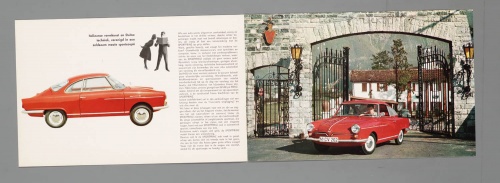

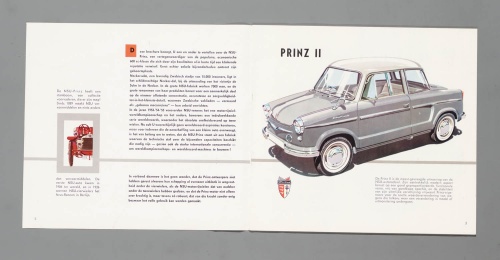

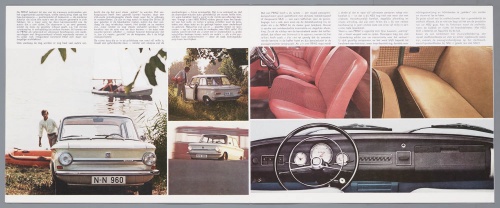

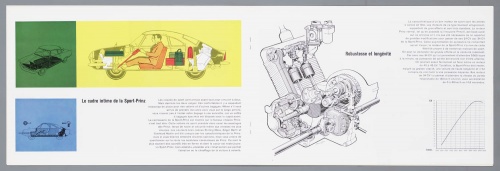

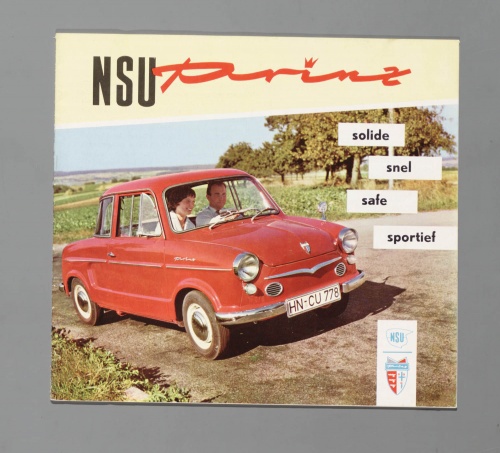

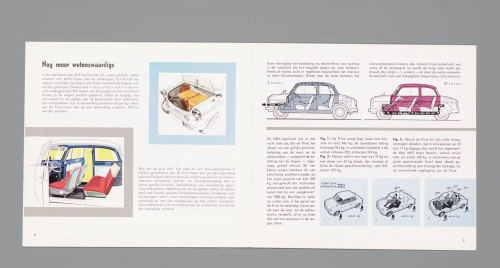

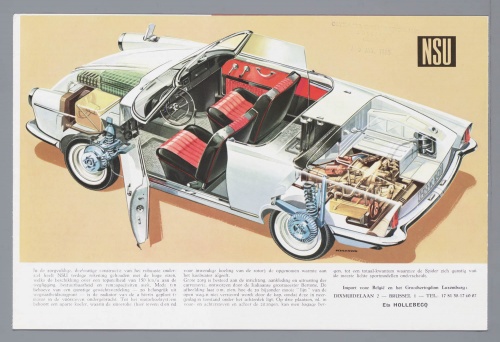

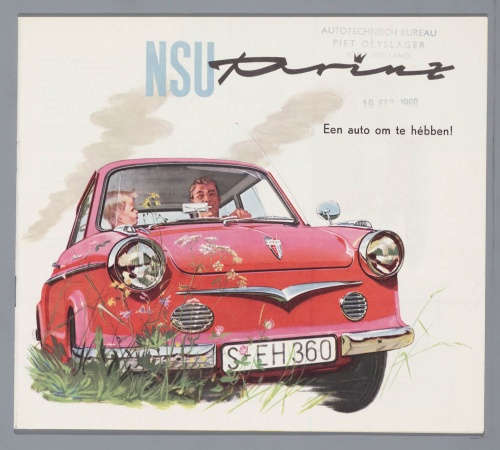

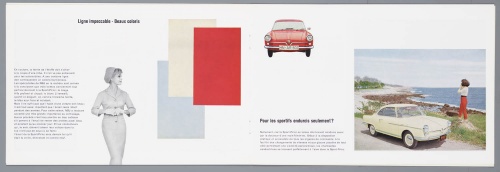

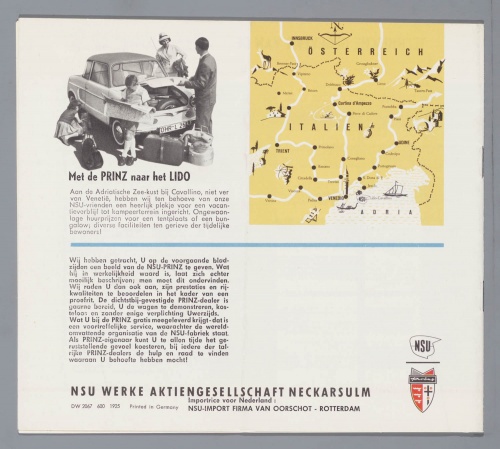

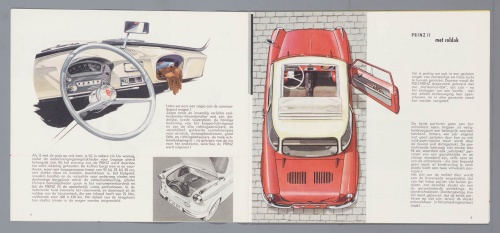

In 1927, the company transferred automobile production to its new site in Heilbronn. Two years later, it began to experience serious financial difficulties and stopped production, selling the plant to FIAT. In 1934-1935, three models were produced at the old Neckarsulm plant, designed by Ferdinand Porsche and becoming the prototypes of the future Volkswagen. This plant fully resumed its activities only in 1958. He presented the minicar model "Prinz" with a 2-cylinder rear-mounted engine with a displacement of 583 cm3 with side valves and an overhead camshaft. The engine turned out to be well suited for boosting: in the basic version for the Prince 600 with a coupe body from Bertone, it developed a power of 30 hp, while the racing versions were 2-3 times more powerful. The next "Prince 1000" showed itself on the race tracks in the late 60s and early 70s. The 4-cylinder engine on the sports version of the Prince-1200TT developed a power of 65 hp, and on the TTS - 70 hp. The general design and body shape of the Prince formed the basis for the second generation of the Soviet Zaporozhets ZAZ-966.

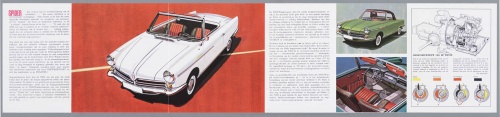

In 1963, the NSU Spider caused a sensation, becoming the world's first car with a 50 hp rotary piston engine. designs by Felix Wankel. The working volume of the combustion chamber of a single-section engine was about 500 cm3. After its production ended in 1967, the company released its most famous passenger model, the Ro-80, equipped with a two-section engine. It was a front-wheel drive sedan with an original sports-style body, which was in many ways ahead of its time and became the object of increased attention in the automotive world. However, the shortcomings of the rotary motor and some other childhood design diseases spoiled its reputation and caused a serious crisis for the company.

In 1969, NSU and Audi merged to form Audi-NSU-Auto Union AG, which became a subsidiary of the Volkswagen concern. A few years later, the K-70 sedan appeared, developed by NSU on the basis of the Ro-80, but with a conventional power unit. In 1977, Volkswagen abandoned further use of the NSU brand.